Best quality Confectionery Production Process - Die forming hard candy production line – Candy

Best quality Confectionery Production Process - Die forming hard candy production line – Candy Detail:

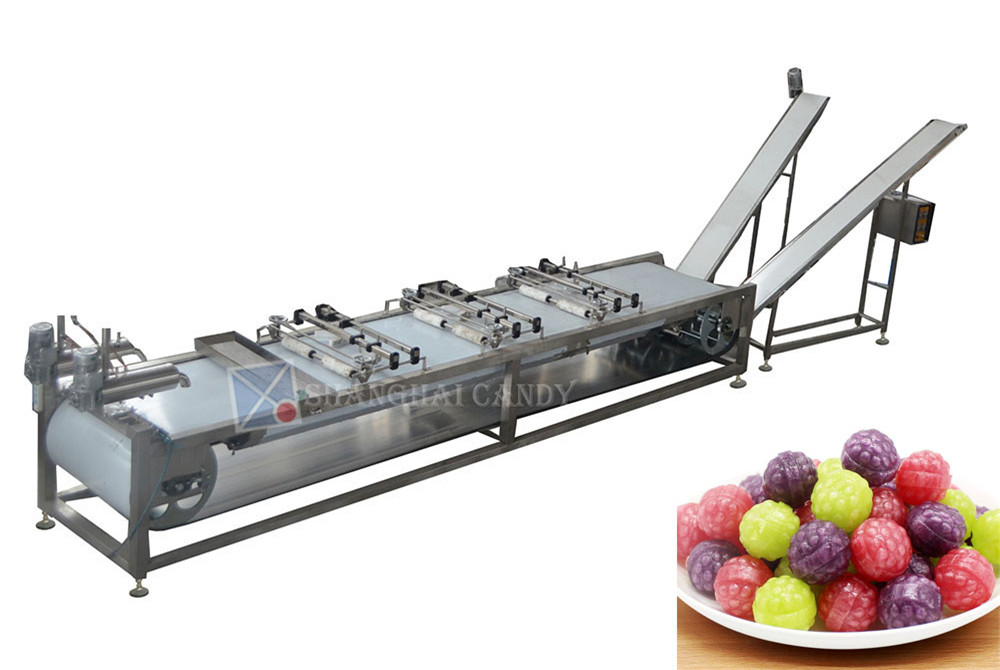

Die forming hard candy line

For production of die formed hard candy, jam center filled hard candy, powder filled hard candy

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming→Forming→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into batch vacuum cooker or micro film cooker through vacuum, heat and concentrated to 145 degrees Celsius.

Step 3

Add flavor, color into syrup mass and it flow onto cooling belt.

Step 4

After cooling, syrup mass is transferred into batch roller and rope sizer, meanwhile can add jam or powder inside. After rope getting smaller and smaller, it enter forming mould, candy formed and transferred for cooling.

Die forming hard candy line Advantages

1. Continuously vacuum cooker, guarantee the quality of sugar mass;

2. Suitable for producing jam or powder center-filled hard candies;

3. Different candy shape can be made by changing the moulds;

4. Automatic running steel cooling belt is optional for better cooling effect.

Application

1. Production of hard candy, powder or jam center filled hard candy.

Die forming hard candy line show

Tech Specs

|

Model |

TY400 |

|

Capacity |

300~400kg/h |

|

Candy Weight |

Shell: 8g(Max); Central filling: 2g(Max) |

|

Rated Output Speed |

2000pcs/min |

|

Total Power |

380V/27KW |

|

Steam Requirement |

Steam Pressure:0.5-0.8MPa; Consumption:200kg/h |

|

Working Condition |

Room Temperature: 20~25℃; Humidity:<55% |

|

Total Length |

21m |

|

Gross Weight |

8000kg |

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Best quality Confectionery Production Process - Die forming hard candy production line – Candy, The product will supply to all over the world, such as: Puerto Rico, Cyprus, Houston, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.