Excellent quality Small Scale Candy Making Equipment - Multifunctional Vacuum Jelly Candy Cooker – Candy

Excellent quality Small Scale Candy Making Equipment - Multifunctional Vacuum Jelly Candy Cooker – Candy Detail:

The syrup is pumped from the dissolver to the upper blending tank by vacuum, under this process, syrup moisture can be removed quickly and concentrated syrup temperature can be cooled down in short time. After reaching required temperature, transfer the prepared gelatin liquor into tank and mix with syrup. Fully mixed gelatin candy mass automatic flow into lower storage tank, ready for next process.

All the required data can be set and displayed on touch screen and all the process can be automatic controlled by PLC program.

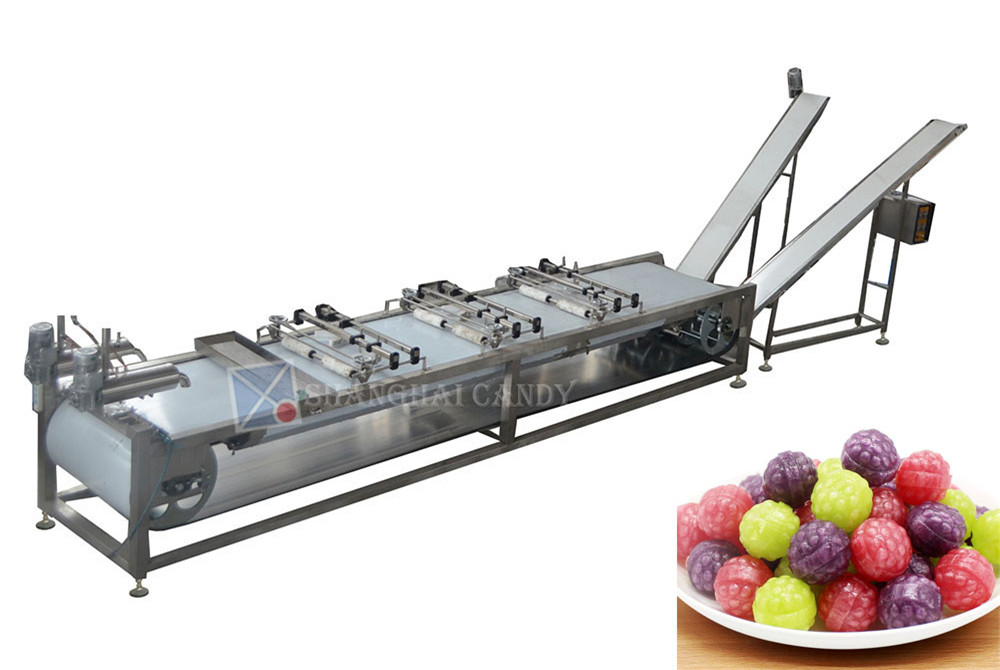

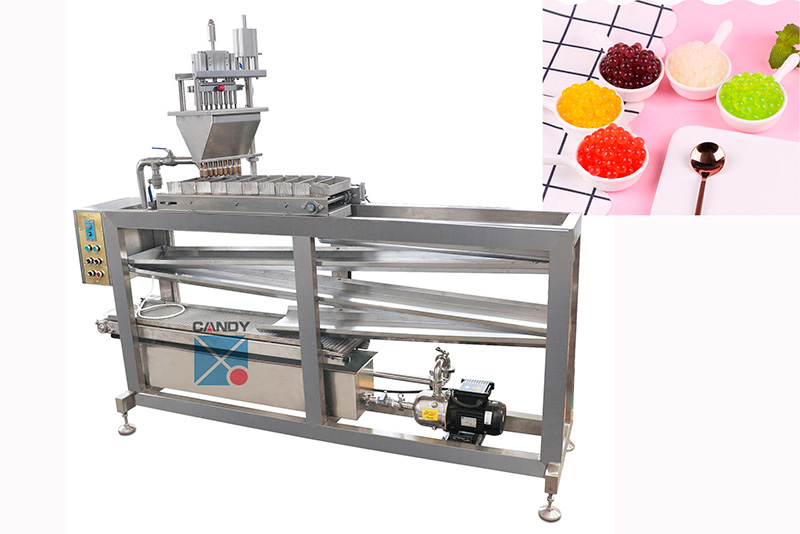

Vacuum Jelly candy cooker

Raw material mixing and storage of jelly candy production

Production flowchart →

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius and store in the storage tank. Gelatin melted with water to be liquid.

Step 2

Boiled syrup mass pump into mixing tank through vacuum, after cooling to 90℃, add liquid gelatin into mixing tank, add citric acid solution, mixing with syrup for few minutes. Then transfer the syrup mass to storage tank.

Vacuum jelly candy Cooker Advantages

1. Whole machine made of stainless steel 304

2. Through the vacuum process, syrup can reduce moisture and cool down in short time.

3. Large touch screen for easy control

Application

1. Production of jelly candy, gummy bear, jelly bean.

Tech Specs

|

Model |

GDQ300 |

|

material |

SUS304 |

|

Heating source |

Electricity or steam |

|

Tank volume |

250kg |

|

Total power |

6.5kw |

|

Vacuum pump power |

4kw |

|

Overall dimension |

2000*1500*2500mm |

|

Gross weight |

800kg |

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for Excellent quality Small Scale Candy Making Equipment - Multifunctional Vacuum Jelly Candy Cooker – Candy, The product will supply to all over the world, such as: Bulgaria, Curacao, Malawi, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.