Factory directly Micro Film Cooker - Automatic Nougat Peanuts candy bar machine – Candy

Factory directly Micro Film Cooker - Automatic Nougat Peanuts candy bar machine – Candy Detail:

Deposit toffee machine

For production of deposited toffee candy, chocolate center filled toffee candy

Production flowchart →

Raw material dissolving→Transporting→Pre-heating→Toffee mass cooking→Add oil and flavor→Storage→Depositing→Cooling→De-moulding→Conveying→Packing→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into toffee cooker through vacuum, cooking to 125 degrees Celsius and store in the tank.

or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 3

Syrup mass is discharged to depositor, flow into hopper for depositing into candy mould. Meanwhile, chocolate fill into the mould from the center filling nozzles.

Step 4

Toffee stay in the mould and transferred into cooling tunnel, after around 20 mins cooling, under the pressure of demoulding plate, toffee drop onto the PVC/PU belt and transferred out.

Deposit toffee candy machine Advantages

1. Sugar and all other materials can be automatic weighed, transferred and mixed through adjust touch screen. Various kinds of recipes can be programmed in the PLC and applied easily and freely when required.

2. PLC, touch screen and servo driven system are world famous brand, more reliable and stable performance and durable use-life. Multi language program can be designed.

3. Long cooling tunnel increase the production capacity.

4. Silicone mould is more efficient for demoulding.

Application

1. Production of toffee candy, chocolate center filled toffee.

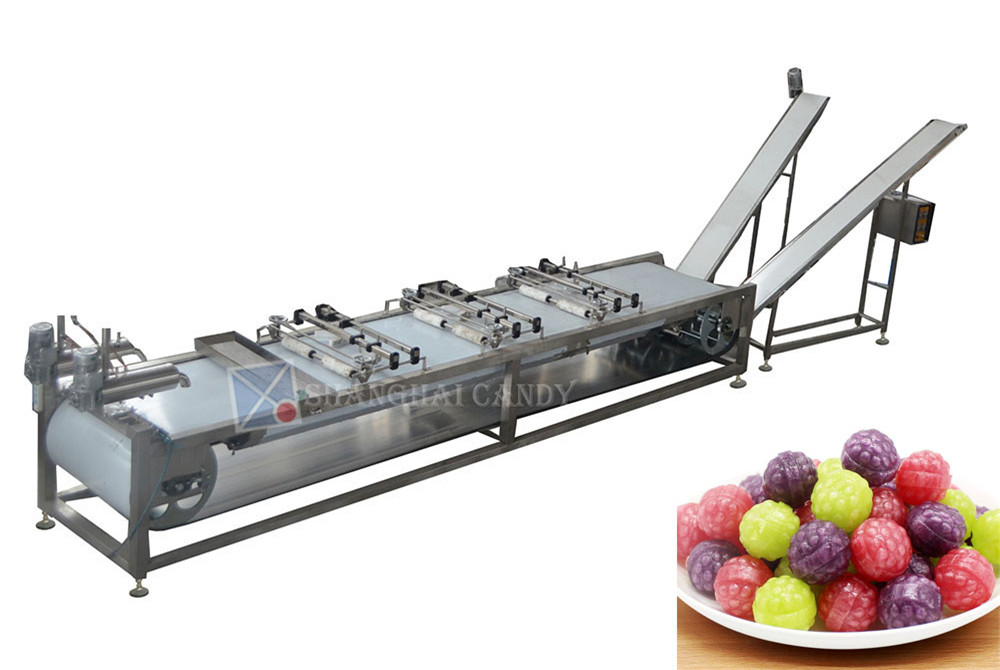

Deposit toffee candy machine show

Tech Specs

|

Model |

SGDT150 |

SGDT300 |

SGDT450 |

SGDT600 |

|

Capacity |

150kg/h |

300kg/h |

450kg/h |

600kg/h |

|

Candy Weight |

As per candy size |

|||

|

Depositing Speed |

45~55n/min |

45~55n/min |

45~55n/min |

45~55n/min |

|

Working Condition |

Temperature: 20~25℃ |

|||

|

Total power |

18Kw/380V |

27Kw/380V |

34Kw/380V |

38Kw/380V |

|

Total Length |

20m |

20m |

20m |

20m |

|

Gross Weight |

3500kg |

4500kg |

5500kg |

6500kg |

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Factory directly Micro Film Cooker - Automatic Nougat Peanuts candy bar machine – Candy, The product will supply to all over the world, such as: Mauritius, Uruguay, Cancun, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.