Factory Outlets Pectin Gummy Machine - Factory supplying die forming lollipop production line – Candy

Factory Outlets Pectin Gummy Machine - Factory supplying die forming lollipop production line – Candy Detail:

Die forming lollipop line

For production of die formed lollipop, gum center filled lollipop

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming→Forming and stick inserting→Final products

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into batch vacuum cooker or micro film cooker through vacuum, heat and concentrated to 145 degrees Celsius.

Step 3

Add flavor, color into syrup mass and it flow onto cooling belt.

Step 4

After cooling, syrup mass is transferred into batch roller and rope size, meanwhile can add gum inside through a extruder. After rope getting smaller and smaller, it enter forming mould, lollipop formed and transferred for cooling.

Die forming lollipop line Advantages

1. Use continuous vacuum cooker, reduce the labor work and increase the production efficiency;

2. Suitable for producing gum center-filled lollipop;

3. Automatic running steel cooling belt is optional for better cooling effect;

4. High speed forming machine is optional for increasing the capacity.

Application

1. Production of lollipop, gum center filled lollipop.

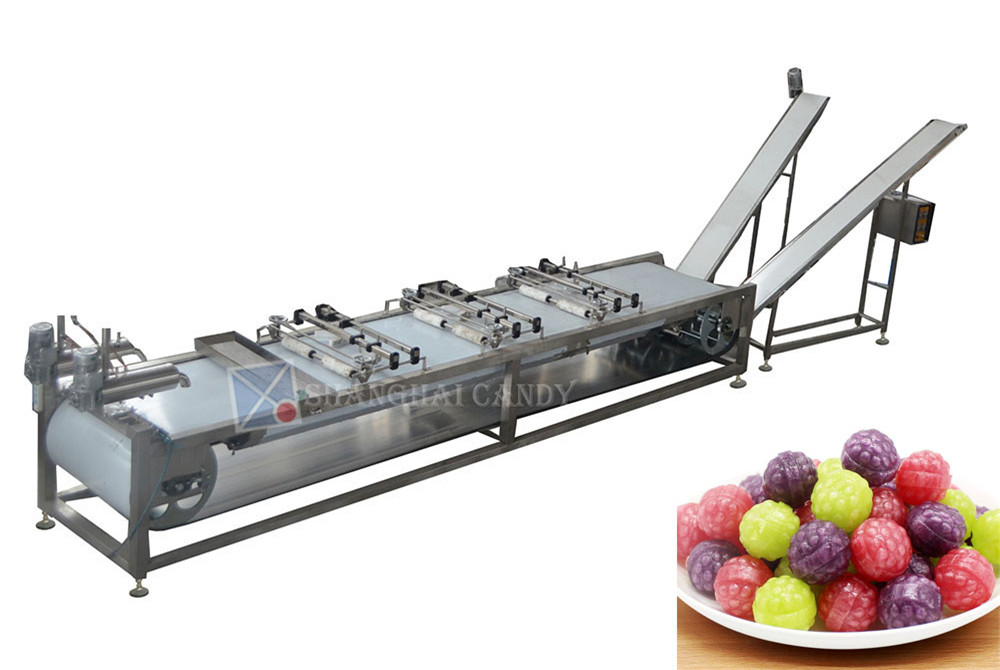

Die forming lollipop line show

Tech Specs

|

Model |

TYB400 |

|

Capacity |

300~400kg/h |

|

Candy Weight |

2~18g |

|

Rated Output Speed |

Max 600pcs/min |

|

Total Power |

380V/18KW |

|

Steam Requirement |

Steam Pressure: 0.5-0.8MPa |

|

Consumption:300kg/h |

|

|

Working Condition |

Room Temperature: <25℃ |

|

Humidity:<55% |

|

|

Total Length |

20m |

|

Gross Weight |

6000kg |

Product detail pictures:

Related Product Guide:

Adhering into the principle of quality, provider, performance and growth, we now have gained trusts and praises from domestic and intercontinental consumer for Factory Outlets Pectin Gummy Machine - Factory supplying die forming lollipop production line – Candy, The product will supply to all over the world, such as: South Korea, Ukraine, San Francisco, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!