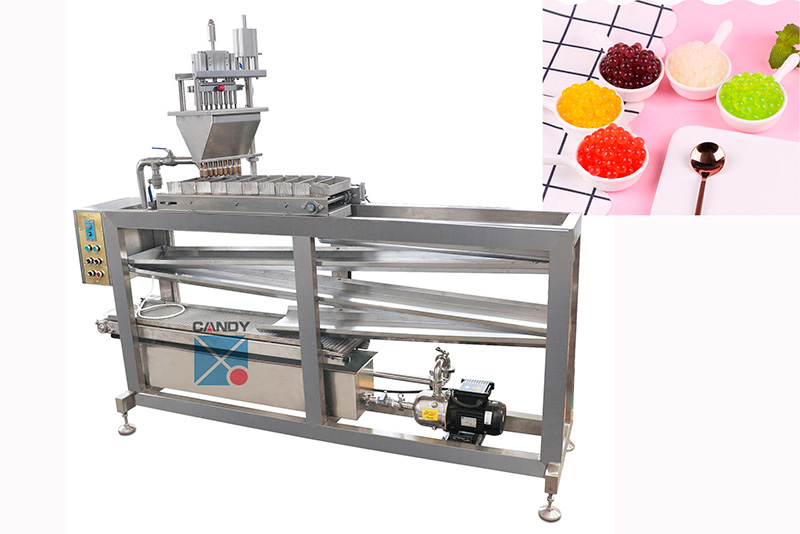

Factory Supply Gummy Candy Manufacturing Equipment - Continuous Soft Candy Vacuum Cooker – Candy

Factory Supply Gummy Candy Manufacturing Equipment - Continuous Soft Candy Vacuum Cooker – Candy Detail:

Continuous Vacuum Cooker

Cooking syrup for soft candy production

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming or extruding→cooling → Forming→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into continuous vacuum cooker, heat and concentrated to 125 degrees Celsius, transfer to the cooling belt for further processing.

Application

1. Production of milk candy, center filled milk candy.

Tech Specs

|

Model |

AN400 |

AN600 |

|

Capacity |

400kg/h |

600kg/h |

|

Stem pressure |

0.5~0.8MPa |

0.5~0.8MPa |

|

Steam consumption |

150kg/h |

200kg/h |

|

Total power |

13.5kw |

17kw |

|

Overall dimension |

1.8*1.5*2m |

2*1.5*2m |

|

Gross weight |

1000kg |

2500kg |

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for Factory Supply Gummy Candy Manufacturing Equipment - Continuous Soft Candy Vacuum Cooker – Candy, The product will supply to all over the world, such as: Thailand, Bulgaria, Argentina, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.