High Quality for Candy Depositor - Ball bubble gum making machine – Candy

High Quality for Candy Depositor - Ball bubble gum making machine – Candy Detail:

PRODUCTION PROCESS

SUGAR MILLING→GUM BASE HEATING→ MIXING MATERIALS→ EXTRUDING→

→CUT AND FORMING→COOLING→COATING→FINISHED

MACHINERY REQUIRED

SUGAR POWDER MACHINE→GUM BASE OVEN→200L MIXER→EXTRUDER→BALL BUBBLE GUM FORMING MACHINE→COOLING TUNNEL→COATING PAN

Ball bubble gum machine Advantages

1. Adopt four screws extruding technique,make the bubble gum organization and have good taste.

1. Adopt three-roller forming technique, suitable for different shapes bubble gum.

2. Adopt horizontal revolving cooling technique to avoid shape distortion

3. Gum size Dia 13mm-25mm as per customer demand

Application

1. Production of ball shape bubble gum

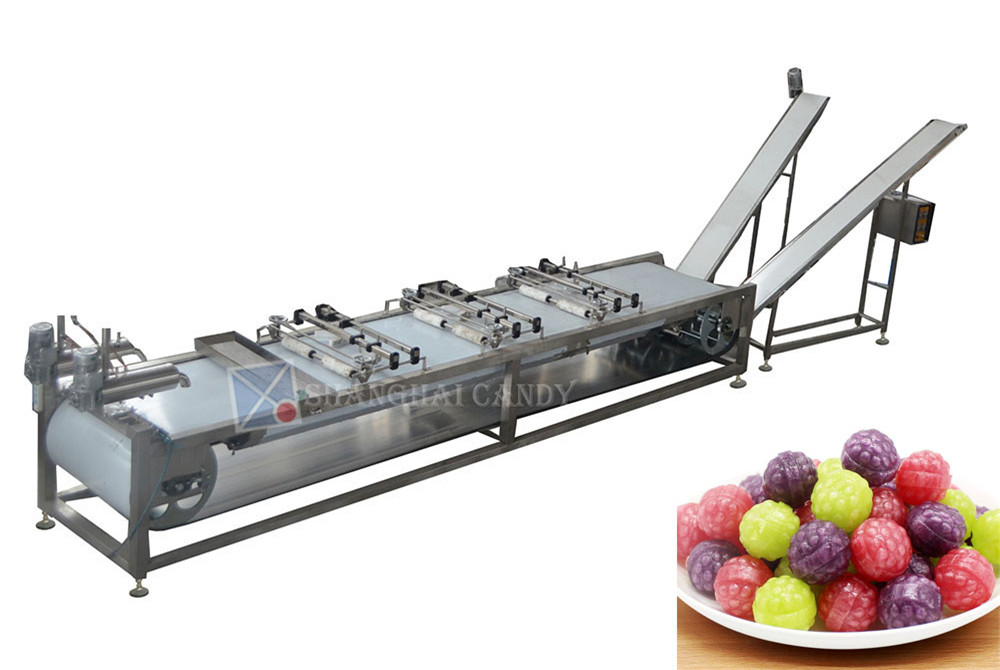

Ball bubble gum machine show

Tech Specs

|

Name |

Install Power(kw) |

Overall Dimension(mm) |

Gross Weight(kg) |

|

Blender |

22 |

2350*880*1200 |

2000 |

|

Extruder(single color) |

7.5 |

2200*900*1700 |

1200 |

|

Forming Machine |

1.5 |

1500*500*1480 |

800 |

|

Cooling Machine |

1.1 |

2000*1400*820 |

400 |

|

Polishing Machine |

2.2 |

1100*1000*1600 |

400 |

|

Capacity |

75~150kg/h |

||

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for High Quality for Candy Depositor - Ball bubble gum making machine – Candy, The product will supply to all over the world, such as: Macedonia, Rio de Janeiro, Australia, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!