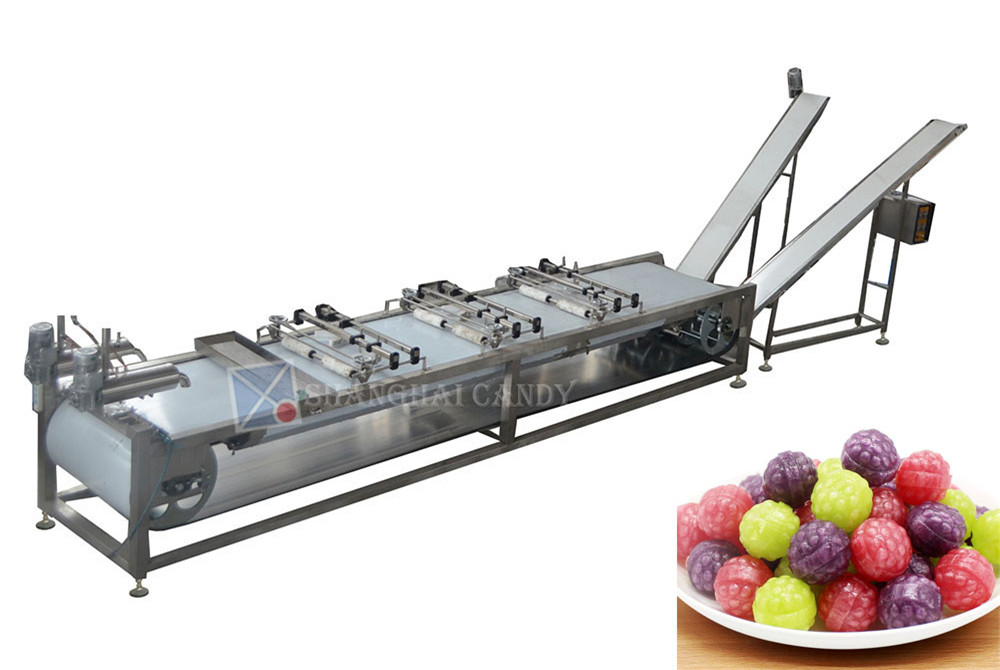

Tuag ua cov khoom qab zib nyuaj ntau lawm kab

Tuag ua cov khoom qab zib nyuaj

Rau kev tsim cov khoom qab zib nyuaj, jam center sau cov khoom qab zib nyuaj, hmoov ntim cov khoom qab zib nyuaj

Ntau lawm flowchart →

Raw khoom dissolving → Cia → Nqus ua noj → Ntxiv xim thiab tsw → Txias → hlua txoj kev → Forming → Cov khoom kawg

Kauj ruam 1

Cov ntaub ntawv raw yog tsis siv neeg los yog manually hnyav thiab muab tso rau hauv lub tank dissolving, boil rau 110 degrees Celsius.

Kauj ruam 2

Boiled syrup loj twj tso kua mis rau hauv batch lub tshuab nqus tsev cooker lossis micro zaj duab xis cooker los ntawm lub tshuab nqus tsev, cua sov thiab concentrated rau 145 degrees Celsius.

Kauj ruam 3

Ntxiv tsw, xim rau hauv syrup loj thiab nws ntws mus rau txoj siv txias.

Kauj ruam 4

Tom qab txias, syrup loj yog pauv mus rau batch roller thiab hlua sizer, lub sijhawm no tuaj yeem ntxiv jam lossis hmoov rau hauv. Tom qab hlua tau me dua thiab me dua, nws nkag mus rau hauv pwm, khoom qab zib tsim thiab xa mus rau qhov txias.

Tuag txoj kev nyuaj khoom qab zib kab Zoo

1. Nruam lub tshuab nqus tsev vacuum, lav qhov zoo ntawm qab zib pawg;

2. Haum rau kev tsim jam los yog hmoov chaw ntim cov khoom qab zib nyuaj;

3. Cov khoom qab zib sib txawv tuaj yeem ua los ntawm kev hloov cov pwm;

4. Tsis siv neeg khiav steel txias txoj siv yog xaiv tau kom zoo dua txias txias.

Daim ntawv thov

1. Kev tsim cov khoom qab zib nyuaj, hmoov lossis jam chaw ntim khoom qab zib nyuaj.

Tuag txoj kev nyuaj khoom qab zib kab qhia

Tech Specs

| Qauv | TSI 400 |

| Muaj peev xwm | 300-400kg / h |

| Khoom qab zib hnyav | Plhaub: 8g (Max); Central filling: 2g (Max) |

| Rated Output Ceev | 2000pcs / min |

| Tag Nrho Lub Zog | 380V / 27KW lub cev muaj zog |

| Chav yuav tsum | Chav Siab: 0.5-0.8MPa; Kev siv: 200kg / h |

| Kev Ua Haujlwm | Chav kub: 20 ~ 25 ℃; Humidity: ± 55% |

| Tag Nrho Ntev | 21m ua |

| Qhov hnyav tag nrho | 8 000kg |