Hot New Products Commercial Gummy Candy Machine - Continuous deposit caramel toffee machine – Candy

Hot New Products Commercial Gummy Candy Machine - Continuous deposit caramel toffee machine – Candy Detail:

Deposit toffee machine

For production of deposited toffee candy, chocolate center filled toffee candy

Production flowchart →

Raw material dissolving→Transporting→Pre-heating→Toffee mass cooking→Add oil and flavor→Storage→Depositing→Cooling→De-moulding→Conveying→Packing→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into toffee cooker through vacuum, cooking to 125 degrees Celsius and store in the tank.

or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 3

Syrup mass is discharged to depositor, flow into hopper for depositing into candy mould. Meanwhile, chocolate fill into the mould from the center filling nozzles.

Step 4

Toffee stay in the mould and transferred into cooling tunnel, after around 20 mins cooling, under the pressure of demoulding plate, toffee drop onto the PVC/PU belt and transferred out.

Deposit toffee candy machine Advantages

1. Sugar and all other materials can be automatic weighed, transferred and mixed through adjust touch screen. Various kinds of recipes can be programmed in the PLC and applied easily and freely when required.

2. PLC, touch screen and servo driven system are world famous brand, more reliable and stable performance and durable use-life. Multi language program can be designed.

3. Long cooling tunnel increase the production capacity.

4. Silicone mould is more efficient for demoulding.

Application

1. Production of toffee candy, chocolate center filled toffee.

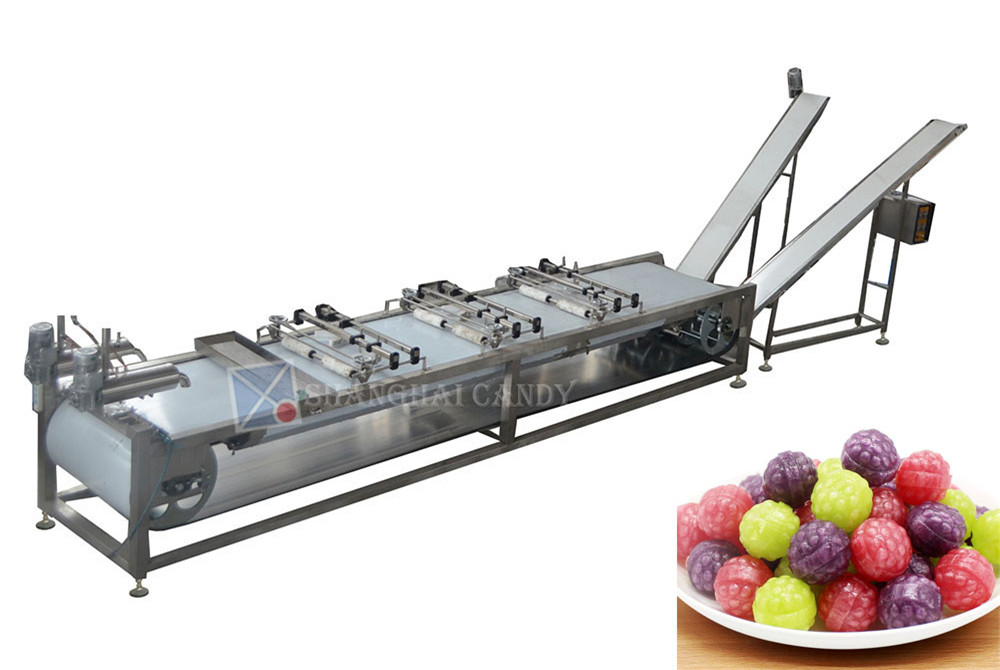

Deposit toffee candy machine show

Tech Specs

|

Model |

SGDT150 |

SGDT300 |

SGDT450 |

SGDT600 |

|

Capacity |

150kg/h |

300kg/h |

450kg/h |

600kg/h |

|

Candy Weight |

As per candy size |

|||

|

Depositing Speed |

45~55n/min |

45~55n/min |

45~55n/min |

45~55n/min |

|

Working Condition |

Temperature: 20~25℃ |

|||

|

Total power |

18Kw/380V |

27Kw/380V |

34Kw/380V |

38Kw/380V |

|

Total Length |

20m |

20m |

20m |

20m |

|

Gross Weight |

3500kg |

4500kg |

5500kg |

6500kg |

Product detail pictures:

Related Product Guide:

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for Hot New Products Commercial Gummy Candy Machine - Continuous deposit caramel toffee machine – Candy, The product will supply to all over the world, such as: Ecuador, Florida, French, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!