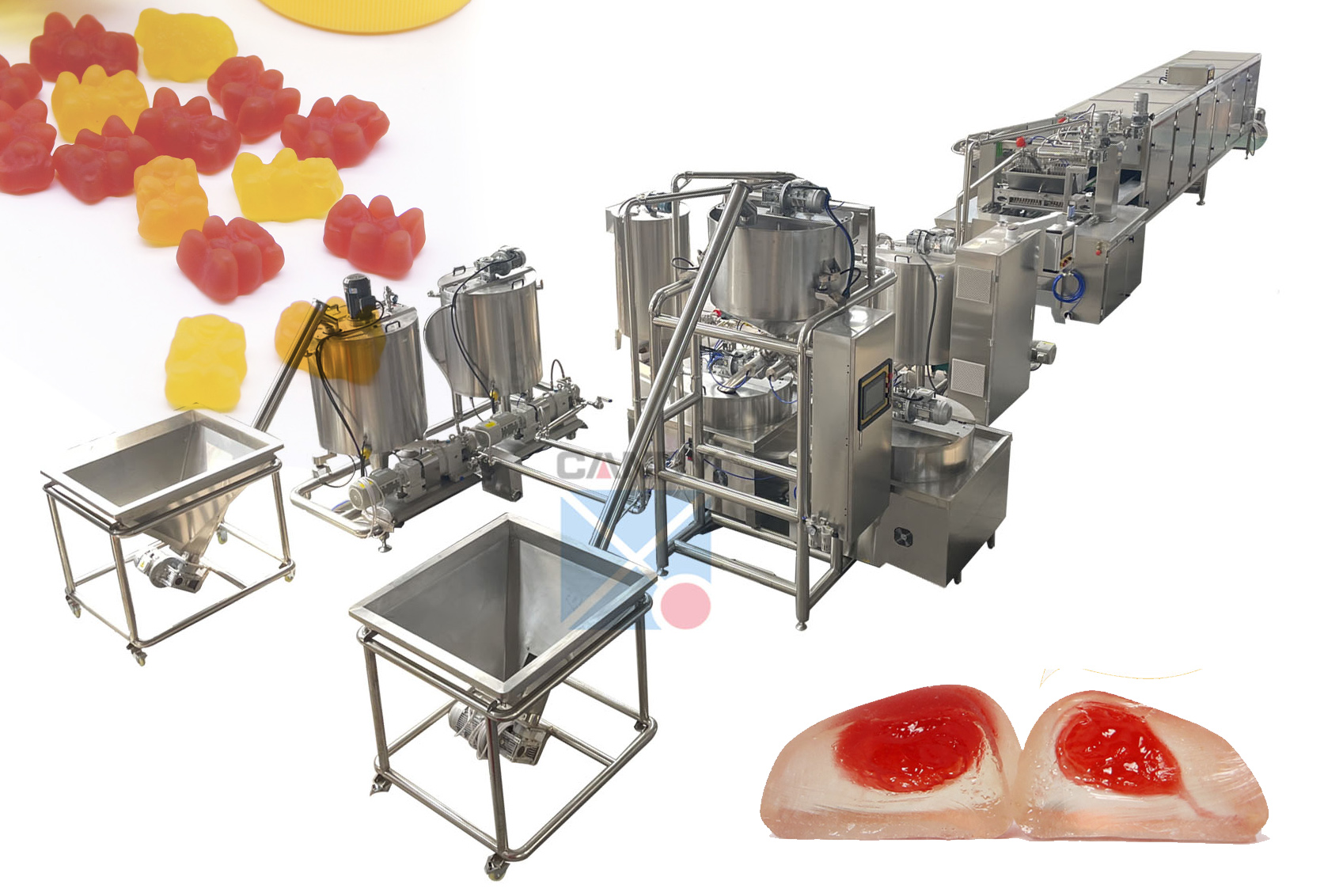

Hot Sale Full Automatic Vitamin Gummy Candy Production Line Bear Making Machine

Depositing machine is an advanced and continuous machine for production of gummy candy by using aluminum or silicone mould. The whole line consists of cooker, steam heating for electrical heating, lobe pump, storage tank, smart depositor, flavor and color dynamic mixer, measuring pump, cooling tunnel with automatic demoulder, Chain conveyor, belt conveyor, sugar or oil coating machine. Ingredients automatic weighing system can be added for higher automation. This line is suitable for confectionery factory to produce all kinds of vitamin gummy candy in single color, two colors or center filling.

depositing machine for Vitamin Gummy Candy

Production flowchart →

Raw material preparation → cooking → Storage → Flavor, color and citric acid automatic dosing→ Depositing→ Cooling→ Demoulding→ Conveying→ drying→ packing→ Final product

Ingredient automatic weighing machine

Capacity: 300-600kg/h

Made of stainless steel 304

Machine included: glucose storage tank, pectin tank,

lobe pump, sugar lifter, weighing machine, cookers

Servo control depositor

Hopper: 2sets jacketed hoppers with oil heating

Made of stainless steel 304

Accessories: manifold plate

Cooling tunnel

Made of stainless steel 304

Colling compressor power: 8kw

Adjustment: cooling temperature adjust range: 0-30 ℃

Quick mounting candy moulds

Made of aluminum allow, coated with teflon

Candy shape can be Custom made

Quick mounting to save time and labor cost

Application

Production of different shaped pectin gummy

Tech Specification:

| Model | SGDQ300 |

| Machine name | Gummy Candy Production Line |

| Capacity | 300kg/h |

| Candy Weight | as per the candy size |

| Depositing Speed | 45 ~55n/min |

| Working Condition |

Temperature:20~25℃; |

| Total power | 45Kw/380V/220V |

| Total Length | 15m |

| Gross Weight | 5000kg |