Manufacturer for Commercial Gummy Machine - Continuous Vacuum Micro film Candy Cooker – Candy

Manufacturer for Commercial Gummy Machine - Continuous Vacuum Micro film Candy Cooker – Candy Detail:

Continuous Vacuum Micro-film Candy Cooker

Cooking syrup for hard candies, lollipop production

Production flowchart →

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius and store in the storage tank.

Step 2

Boiled syrup mass pump into preheat tank through dosing pump, there is core pipe inside the preheat tank, steam heating outside of core pipe, thus syrup get heated inside of core pipe. Preheat tank connected to vacuum pump, it makes the whole vacuum space among dosing pump to discharge pump, preheat tank, micro film chamber. Syrup from preheat tank transfer to micro film tank, scrape into a thin film by rotary blades and heated to 145 degrees Celsius. Then syrup drop to discharge pump and transfer out. The whole working process is continuous.

1-dosing pump 2-preheat tank 3-core pipe 4-vacuum micro film chamber

5-vacuum pump 6-main shaft 7-scrape roller 8-blades 9-discharge pump 10-outlet pipe

Step 3

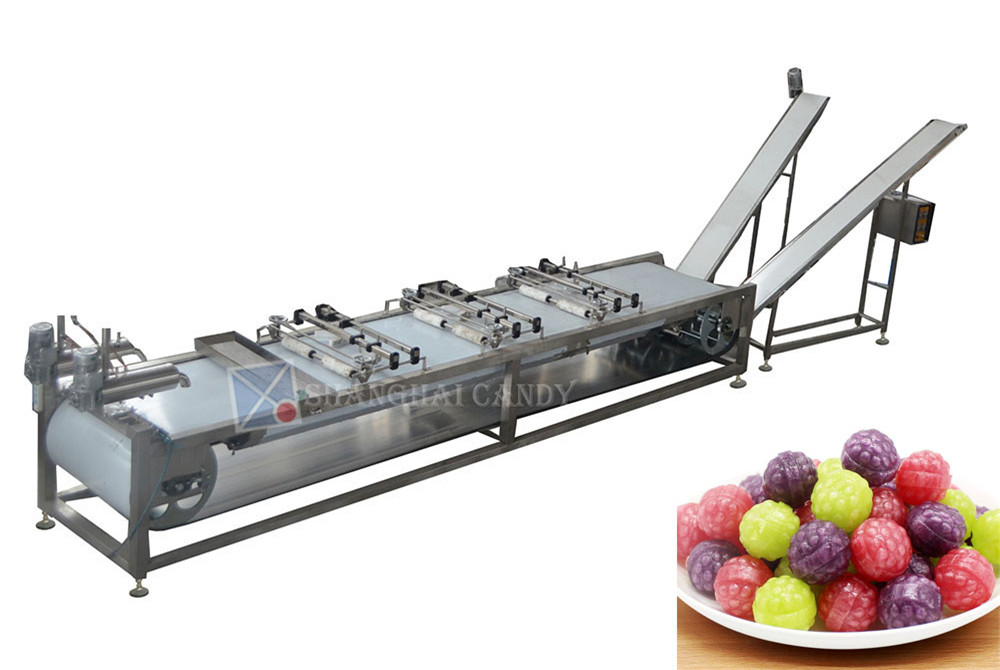

Cooked syrup can be transferred to deposit machine or cooling belt for further process.

Continuous Vacuum Micro-film Candy Cooker Advantages

1. Whole machine made of stainless steel 304

2. Continuous cooking reduce the labor work and improve the production efficiency

3. Different capacity is for optional

4. Large touch screen for easy control

5. Syrup cooked by this machine has good quality

Application

1. Production of hard candy, lollipop

Tech Specs

|

Model |

AGD150 |

AGD300 |

AGD450 |

AGD600 |

|

Capacity |

150kg/h |

300kg/h |

450kg/h |

600kg/h |

|

Steam consumption |

120kg/h |

200kg/h |

250kg/h |

300kg/h |

|

Stem pressure |

0.5~0.8MPa |

0.5~0.8MPa |

0.5~0.8MPa |

0.5~0.8MPa |

|

Electric power needed |

12.5kw |

13.5kw |

15.5kw |

17kw |

|

Overall dimension |

2.3*1.6*2.4m |

2.3*1.6*2.4m |

2.4*1.6*2.4m |

2.5*1.6*2.4m |

|

Gross weight |

900kg |

1000kg |

1100kg |

1300kg |

Product detail pictures:

Related Product Guide:

We pursue the management tenet of Quality is remarkable, Company is supreme, Name is first, and will sincerely create and share success with all clientele for Manufacturer for Commercial Gummy Machine - Continuous Vacuum Micro film Candy Cooker – Candy, The product will supply to all over the world, such as: Hanover, Czech, Romania, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.