Massive Selection for Gum Machine - Continuous Soft Candy Vacuum Cooker – Candy

Massive Selection for Gum Machine - Continuous Soft Candy Vacuum Cooker – Candy Detail:

Continuous Vacuum Cooker

Cooking syrup for soft candy production

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming or extruding→cooling → Forming→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into continuous vacuum cooker, heat and concentrated to 125 degrees Celsius, transfer to the cooling belt for further processing.

Application

1. Production of milk candy, center filled milk candy.

Tech Specs

|

Model |

AN400 |

AN600 |

|

Capacity |

400kg/h |

600kg/h |

|

Stem pressure |

0.5~0.8MPa |

0.5~0.8MPa |

|

Steam consumption |

150kg/h |

200kg/h |

|

Total power |

13.5kw |

17kw |

|

Overall dimension |

1.8*1.5*2m |

2*1.5*2m |

|

Gross weight |

1000kg |

2500kg |

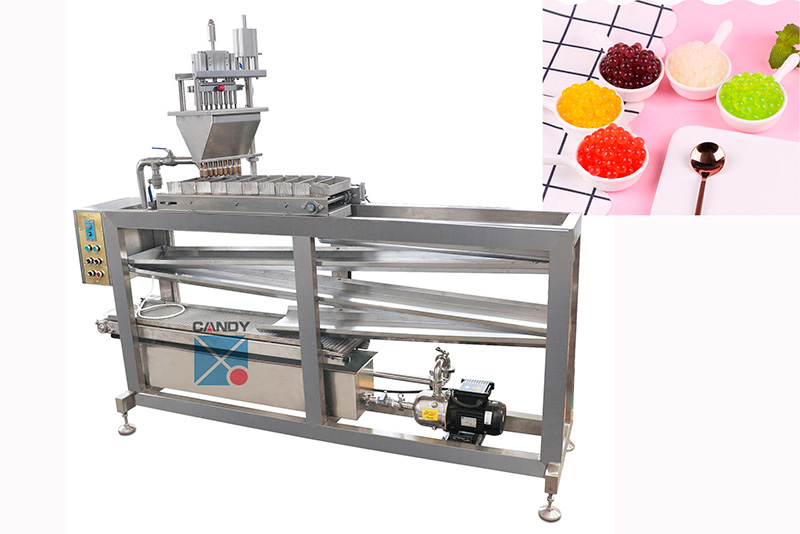

Product detail pictures:

Related Product Guide:

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for Massive Selection for Gum Machine - Continuous Soft Candy Vacuum Cooker – Candy, The product will supply to all over the world, such as: Gambia, Cape Town, Bahrain, We've got more than 10 years experience of production and export business. We always develop and design kinds of novel items to meet the market demand and help the guests continuously by updating our goods. We've been specialized manufacturer and exporter in China. Wherever you are, make sure you join us, and together we will shape a bright future in your business field!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.