New Delivery for Chewing Gum Productions Line - Die forming milk candy machine – Candy

New Delivery for Chewing Gum Productions Line - Die forming milk candy machine – Candy Detail:

Die forming milk candy line

For production of die formed milk candy, center filled soft candy

Production flowchart →

Raw material dissolving→Storage→Vacuum cooking→Add color and flavor→Cooling→Rope forming or extruding→cooling → Forming→Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius.

Step 2

Boiled syrup mass pump into air inflation cooker or continuous cooker, heat and concentrated to 125 degrees Celsius.

Step 3

Add flavor, color into syrup mass and it flow onto cooling belt.

Step 4

After cooling, syrup mass is transferred into extruder, rope sizer, meanwhile can add jam filling inside. After rope getting smaller and smaller, it enter into forming mould, candy formed and transferred for cooling.

Die forming milk candy line Advantages

*Automatic control for vacuum cooking and aeration mixing process;

*An unique design of aeration mixing system guarantees a high quality product;

*Synchronized control for central-filling,extruding and rope sizing;

*Chain style die for different shapes of candy;

*Steel cooling belt is optional for better cooling effect;

*Pulling machine is optional for pulled (aerated) candy requirement.

Application

1. Production of milk candy, center filled milk candy.

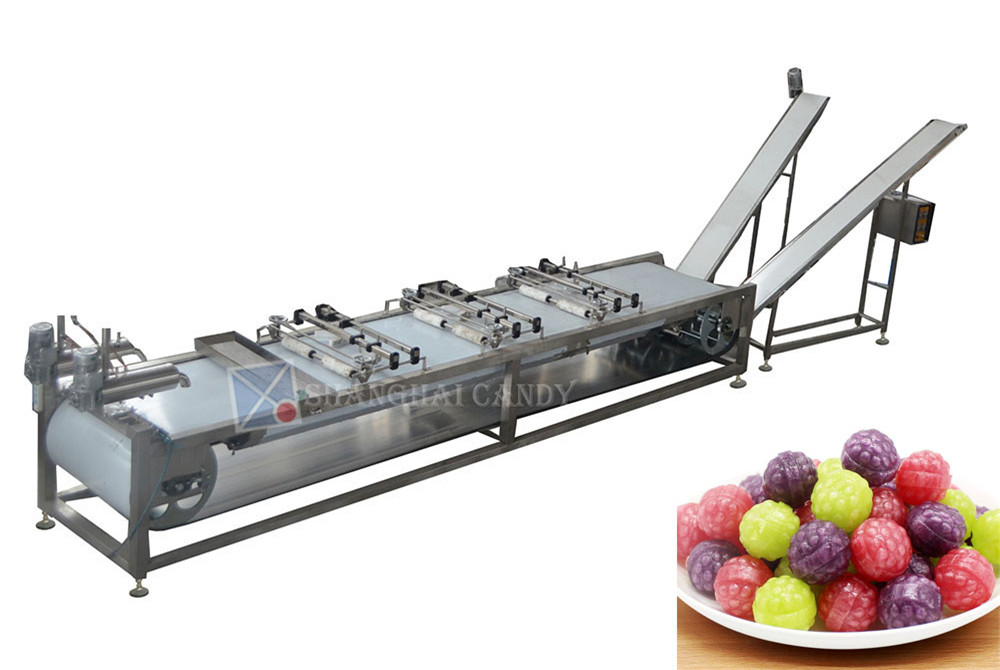

Die forming milk candy line show

Tech Specs

|

Model |

T400 |

|

Standard Capacity |

300-400kg/h |

|

Candy Weight |

Shell:8g(Max); Central filling: 2g(Max) |

|

Rated Output Speed |

1200pcs/min |

|

Electric Power |

380V/60KW |

|

Steam Requirement |

Steam Pressure:0.2-0.6MPa; Consumption:250~400kg/h |

|

Working Condition |

Room Temperature: 20~25℃; Humidity: 55% |

|

Total Length |

16m |

|

Gross Weight |

5000kg |

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for New Delivery for Chewing Gum Productions Line - Die forming milk candy machine – Candy, The product will supply to all over the world, such as: Mongolia, Guatemala, Grenada, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!