Rapid Delivery for Chewing Gum Machines - Servo control deposit gummy jelly candy machine – Candy

Rapid Delivery for Chewing Gum Machines - Servo control deposit gummy jelly candy machine – Candy Detail:

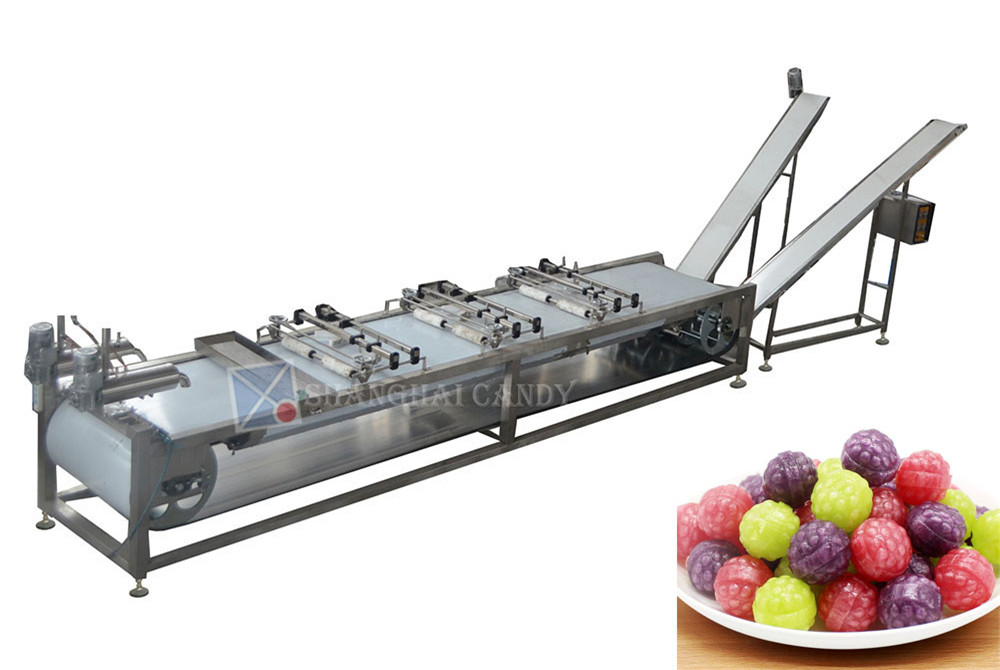

Deposit jelly candy machine

For production of deposited jelly candy, gummy bear, jelly bean etc

Production flowchart →

Gelatin melting→ Sugar & glucose boiling→ Add melt gelatin into cooled syrup mass → Storage→ Add flavor, color and citric acid→ Depositing→ Cooling→ Demoulding→ Conveying→ drying→ packing→ Final product

Step 1

Raw materials are automatic or manually weighed and put into dissolving tank, boil to 110 degrees Celsius and store in the storage tank. Gelatin melted with water to be liquid.

Step 2

Boiled syrup mass pump into mixing tank through vacuum, after cooling to 90℃, add liquid gelatin into mixing tank, add citric acid solution, mixing with syrup for few minutes. Then transfer the syrup mass to storage tank.

Step 3

Syrup mass is discharged to depositor, after mixing with flavor & color, flow into hopper for depositing into candy mould.

Step 4

Candy stay in the mould and transferred into cooling tunnel, after around 10 mins cooling, under the pressure of demoulding plate, candy drop onto the PVC/PU belt and transferred to do sugar coating or oil coating.

Step 5

Put jelly candies onto trays, keep each candy separately to avoid sticking together and send to drying room. Drying room should install Air conditioner/heater and dehumidifier to keep suitable temp.and humidity. After drying, jelly candies can be transferred for packaging.

Deposit jelly candy machine Advantages

1. Sugar and all other materials can be automatic weighed, transferred and mixed through adjust touch screen. Various kinds of recipes can be programmed in the PLC and applied easily and freely when required.

2. PLC, touch screen and servo driven system are world famous brand, more reliable and stable performance and durable use-life. Multi language program can be designed.

3. Machine has oil sprayer and oil mist absorb fan, make the demoulding more easily.

4. Unique designed gelatin mixing and storage tank can shorten the cooling time and taken more moisture, increase the production speed.

5. Using with high speed air aeration machine, this machine can produce marshmallow jelly candies.

Application

1. Production of jelly candy, gummy bear, jelly bean.

2. Production marshmallow jelly candies

3. Production of multi-color jelly candies

Deposit jelly candy machine show

Tech Specs

| Model | SGDQ150 | SGDQ300 | SGDQ450 | SGDQ600 |

| Capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

| Candy Weight | as per the candy size | |||

| Depositing Speed | 45 ~55n/min | 45 ~55n/min | 45 ~55n/min | 45 ~55n/min |

| Working Condition |

Temperature: 20~25℃ |

|||

| Total power | 35Kw/380V | 40Kw/380V | 45Kw/380V | 50Kw/380V |

| Total Length | 18m | 18m | 18m | 18m |

| Gross Weight | 3000kg | 4500kg | 5000kg | 6000kg |

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Rapid Delivery for Chewing Gum Machines - Servo control deposit gummy jelly candy machine – Candy, The product will supply to all over the world, such as: Mauritania, Melbourne, America, When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we're able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.